Testing Facilities

rigorous testing processes guarantee the durability, resilience, and

performance of our products across various industries.

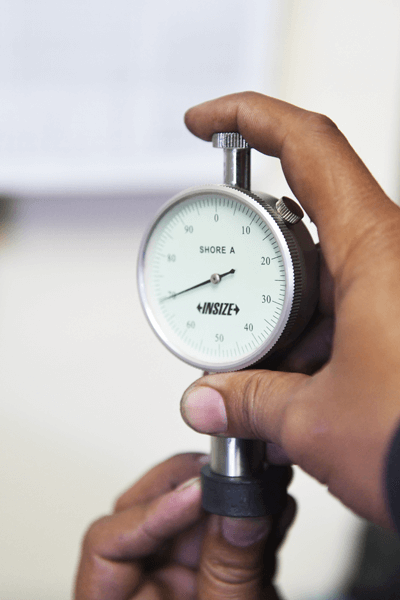

Hardness Testing

Rheology Test

The curing properties of rubber com pounds are assessed following ASTM standards D5289-17 and D2084-17, utilizing Rotor-less Rheometers (MDR-A

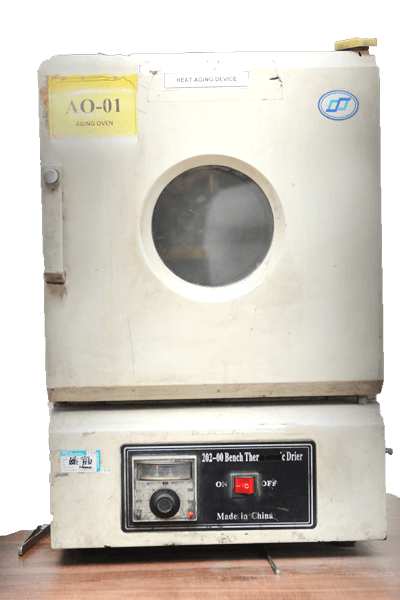

Heat Aging

Solid rubber specimen’s resistance to aging is evaluated per ASTM D 573-04(2015) standards, employing a heat aging oven for testing

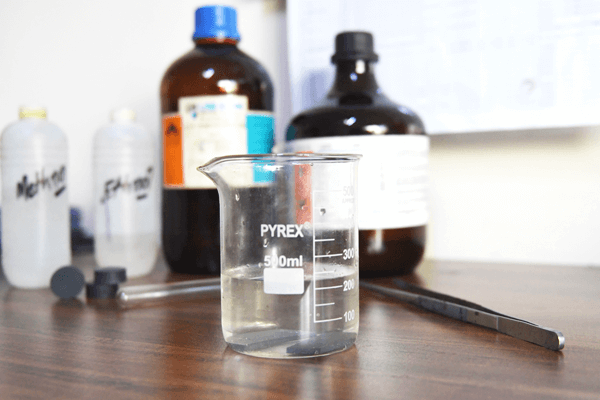

Fuel and Oil Resistance Test

The examination of resistance to fuel and oil in cured rubber specimens is conducted using equipment such as the Mettler balance and an oven, following the ASTM D471 test method.

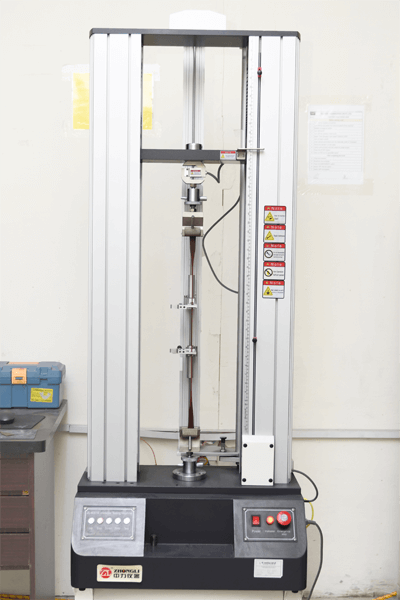

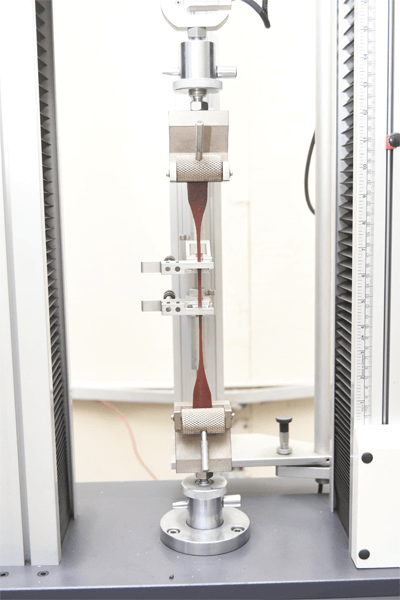

Tensile Test

The Tensile Strength of cured rubber specimens is evaluated using the ASTM D412-16 test method on a Universal Tensile Tester

Tear Strength

The force needed to tear a cured rubber specimen is assessed following ASTM D624-00e1 standards, employing a Uni versal Tensile Tester for accurate measurement.

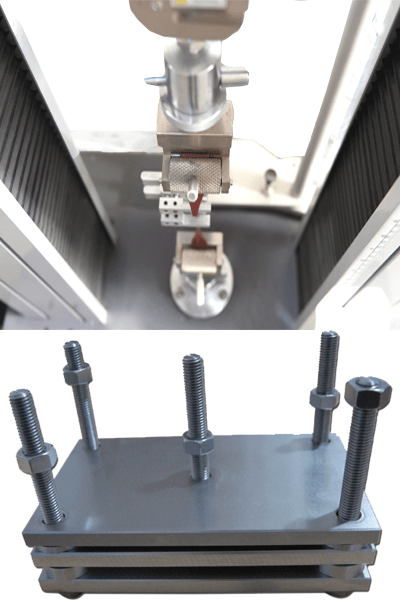

Compression Test

The assessment of rubber’s permanent deformation under elevated temperatures adheres to the ASTM D39 test procedure.

Ozone Resistance

The resistance to ozone of solid rubber specimens is assessed following ASTM D1149-16 standards, utilizing an Ozone Chamber for testing purposes.

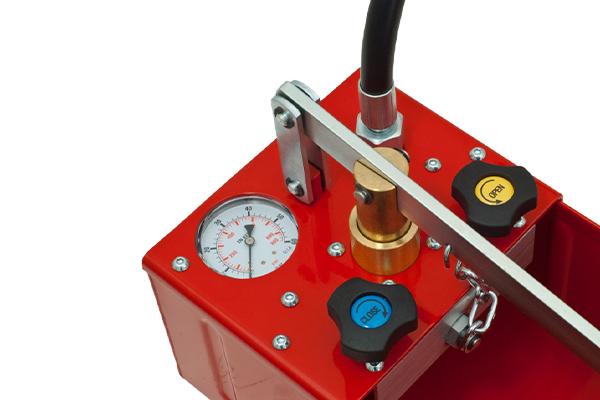

Pressure Resistance Test

The resistance to pressure of rubber hoses is evaluated according to test methods SAE J 20-03 and SAE J 30-12, utilizing a pressure tester machine for accurate measurement.

© Copyright 2024 NRC | All Rights Reserved | Powered by PakCreation